Automation

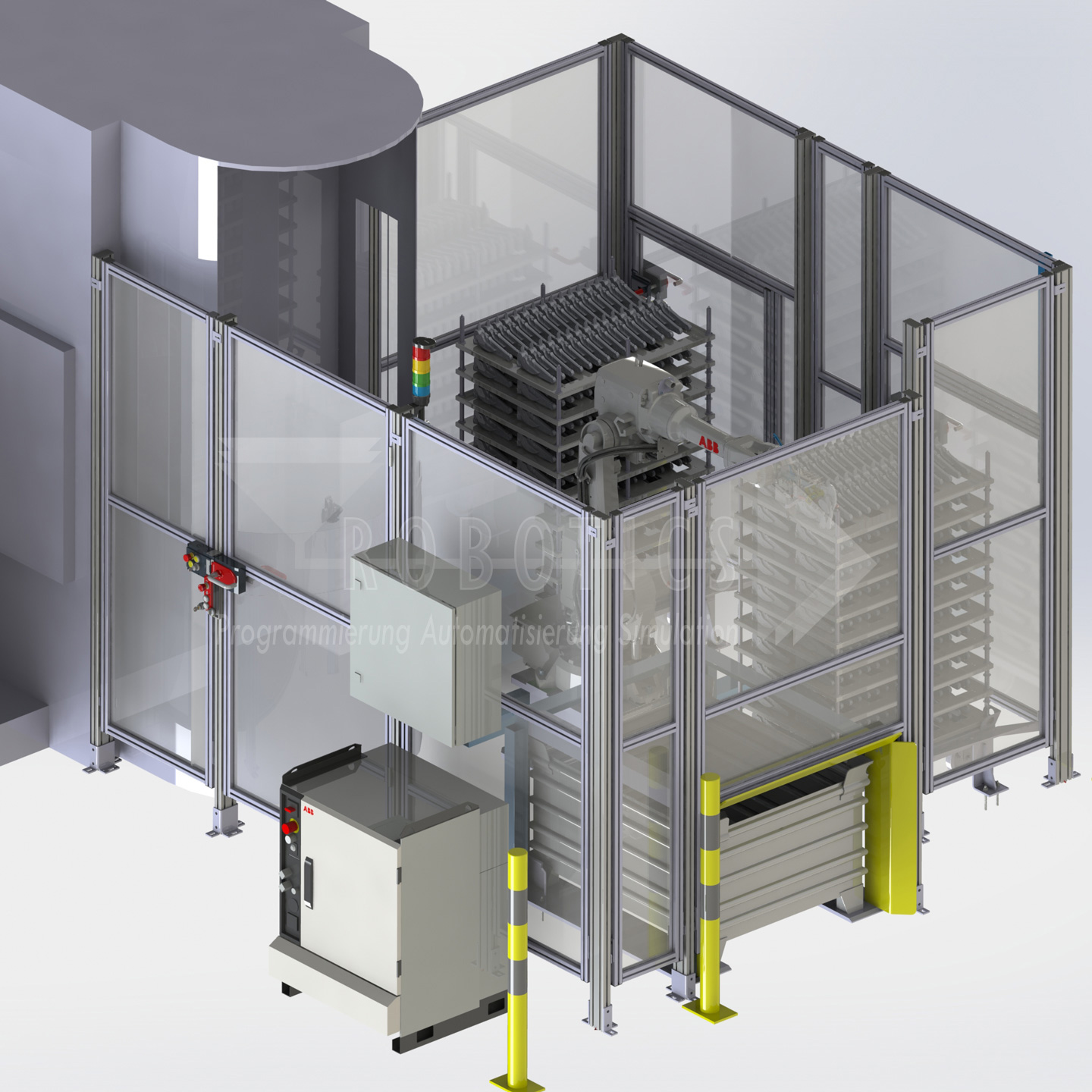

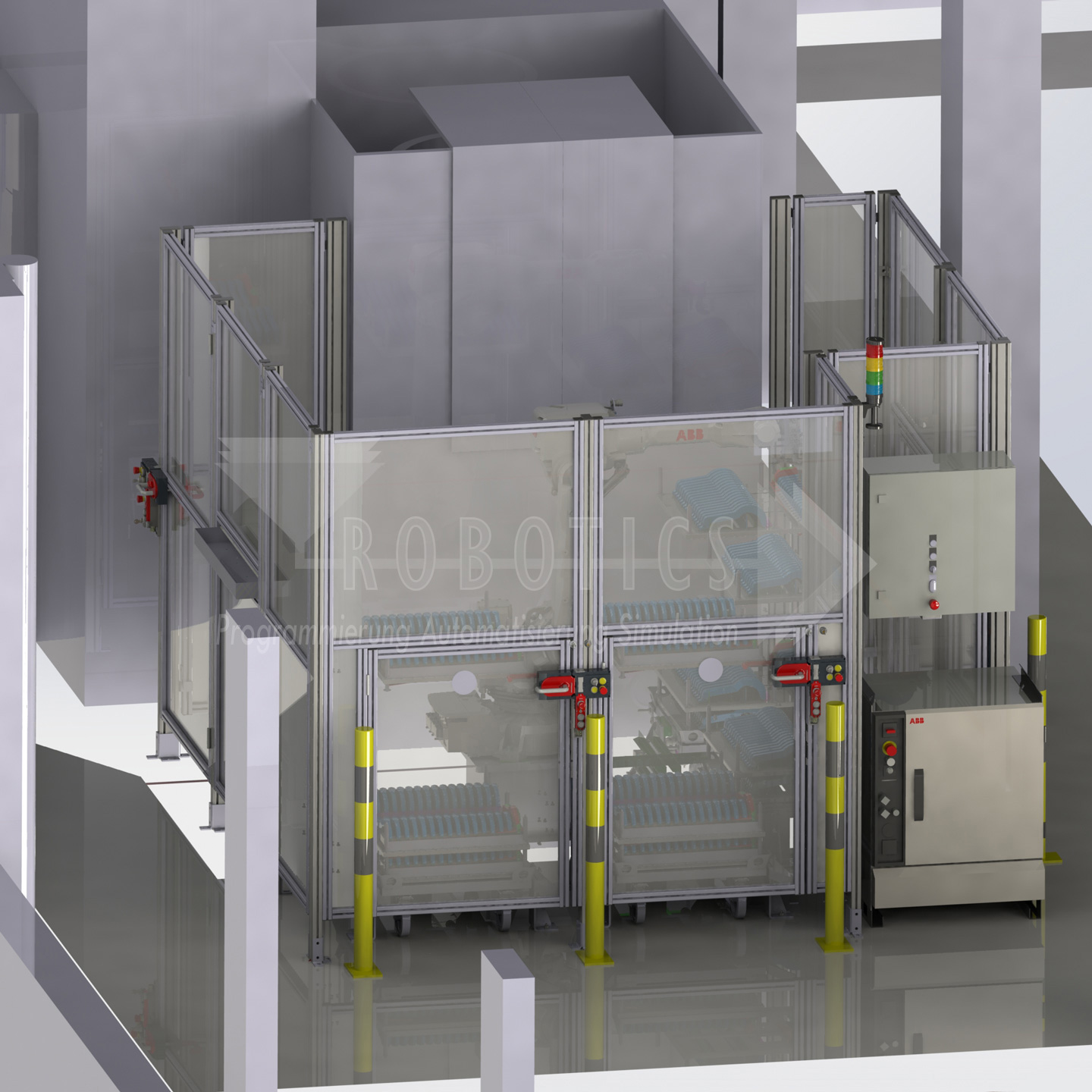

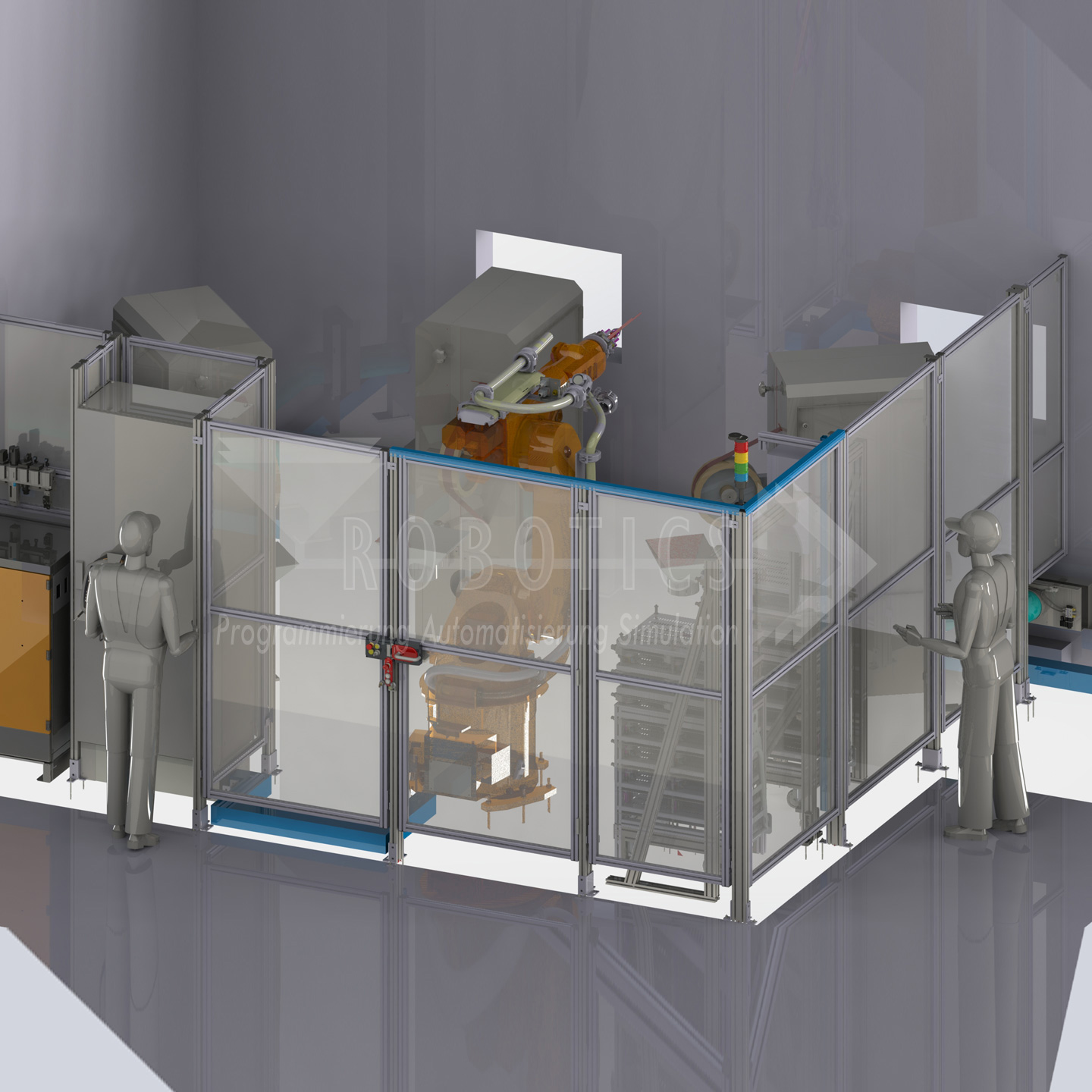

“Our robot cells enable SMEs to efficiently and ideally automate their production facilities.”

Benefits of 3D process simulation for SMEs

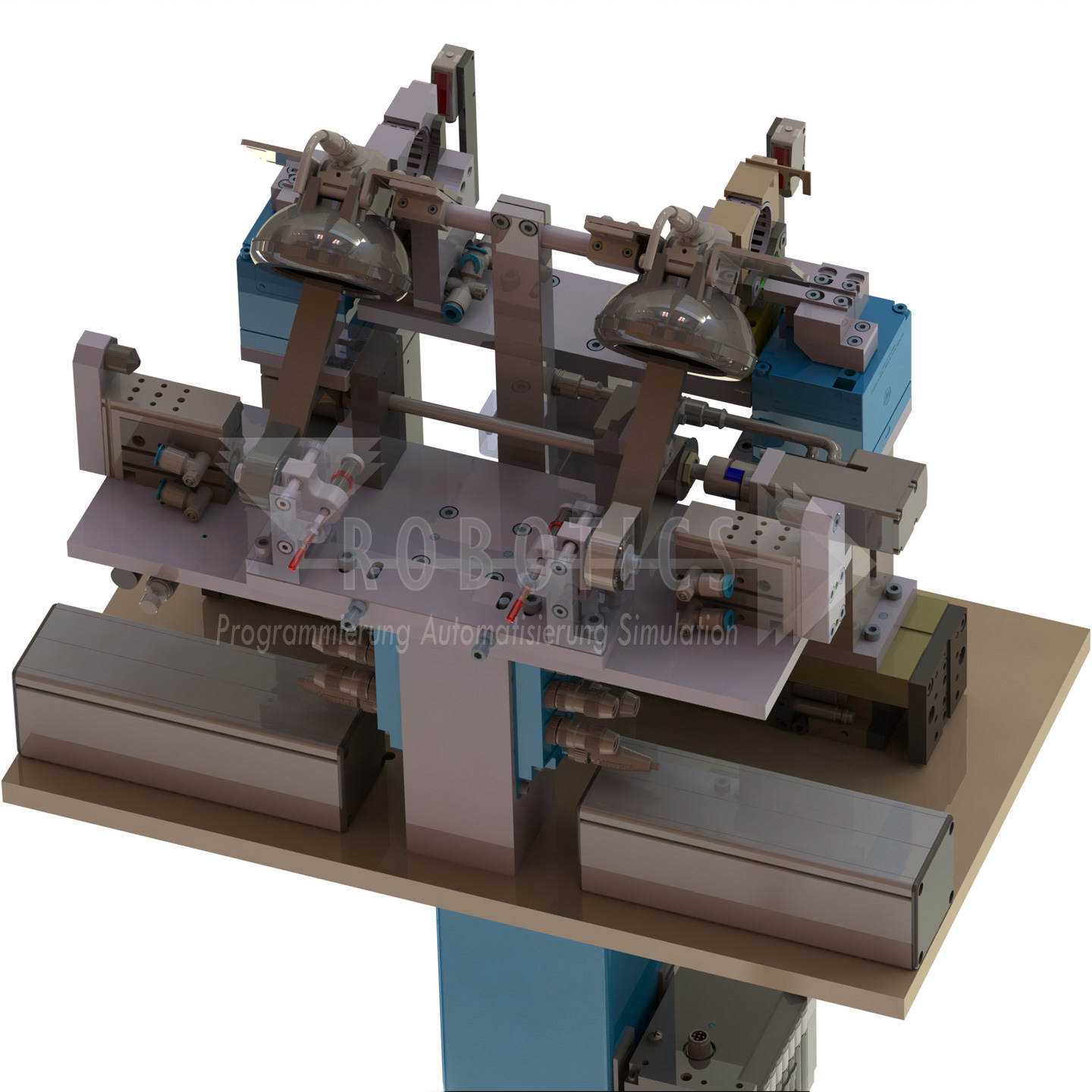

- Sustainable cost savings thanks to extensive preliminary investigations using 3D systems

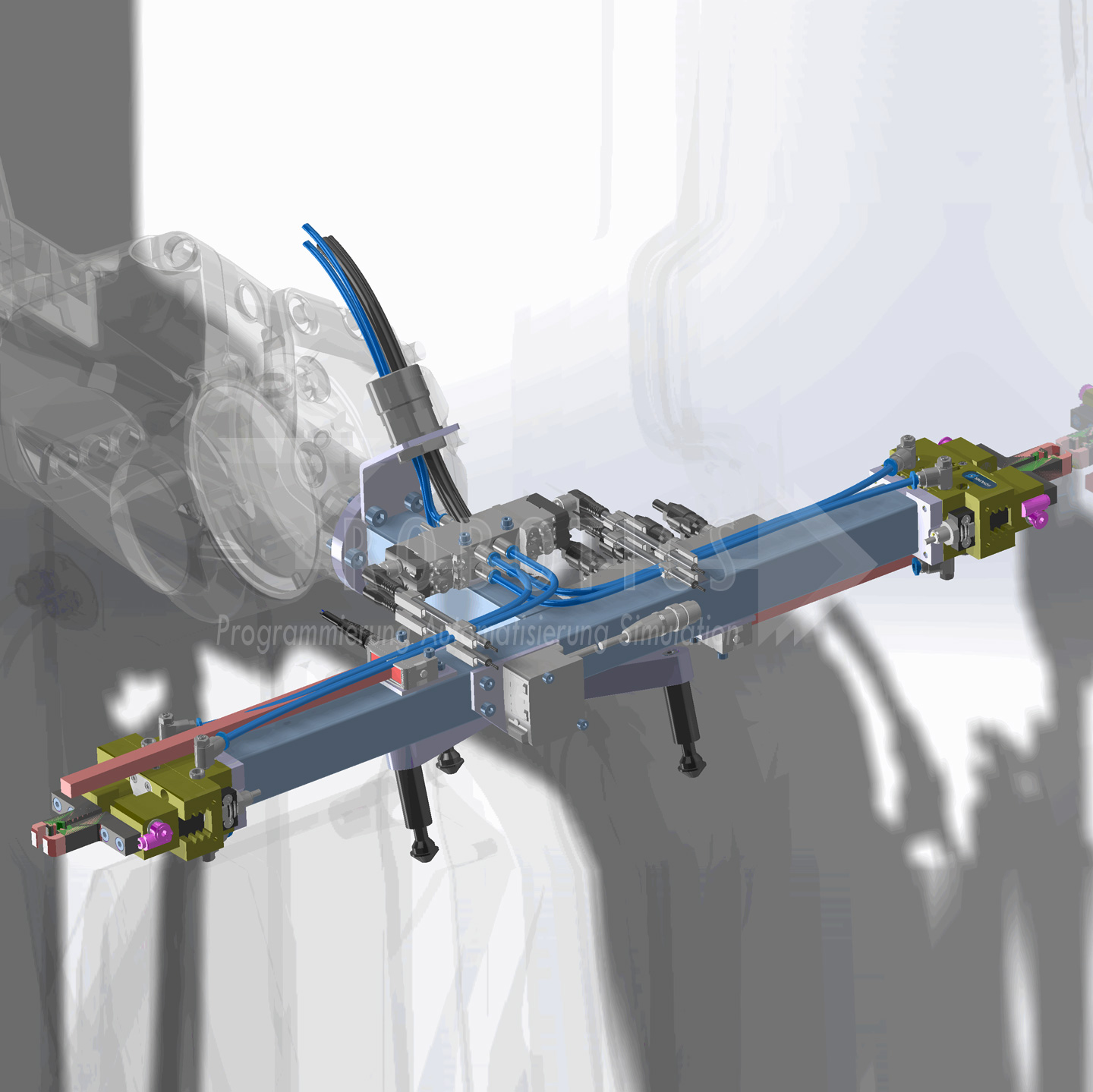

- Flexible solutions, e.g. with vision systems

- Accurate positioning of all components is also possible for several production types

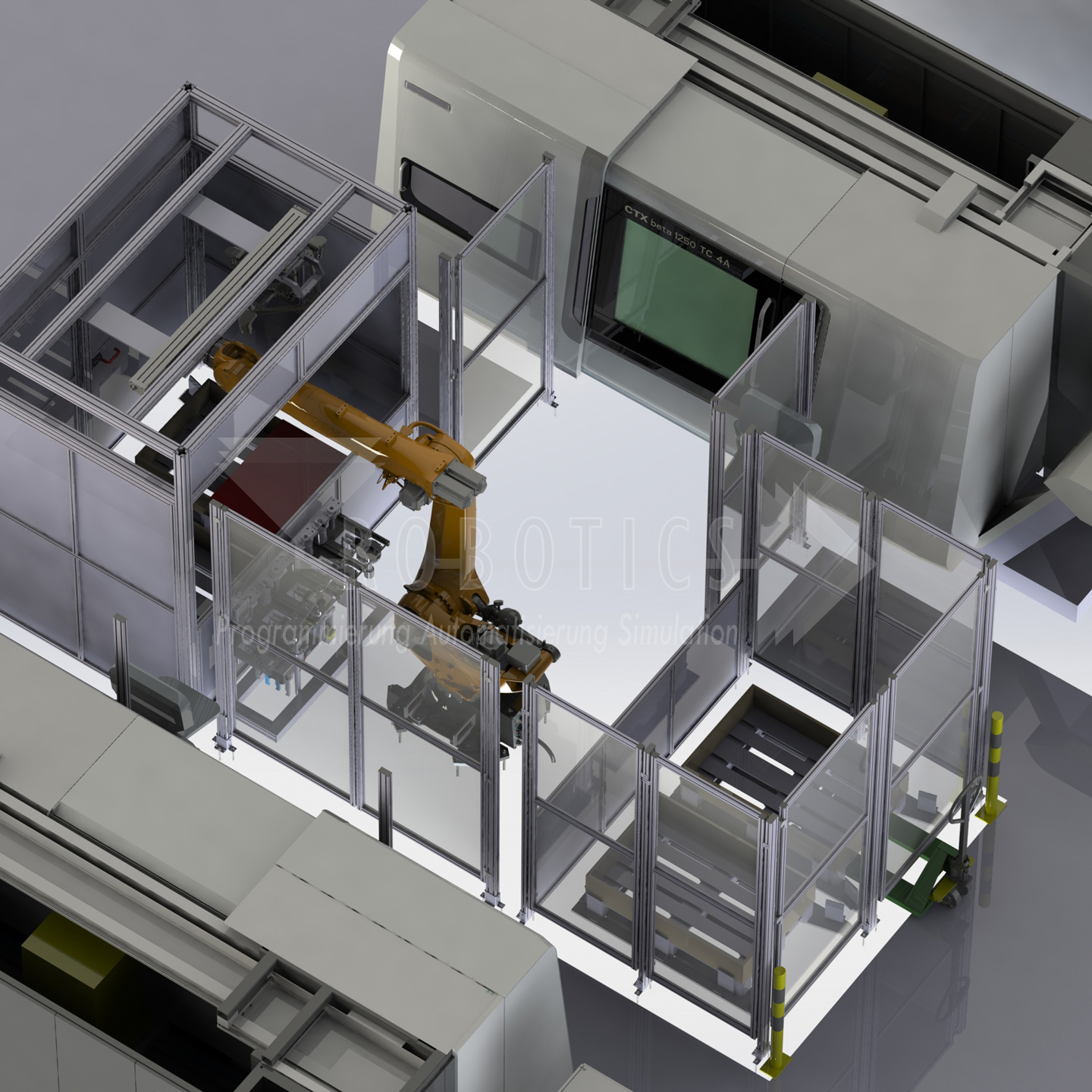

- Integration into existing installations and/or installation sections

Benefits to companies of using robot cells

Companies that have currently integrated robots into their manufacturing achieve the following benefits:

- Improved adherence to delivery dates

- Greater added value per capita

- Lower reject rate in production

- Introduction of new organisational principles within the company

Project Procedure

Simulation

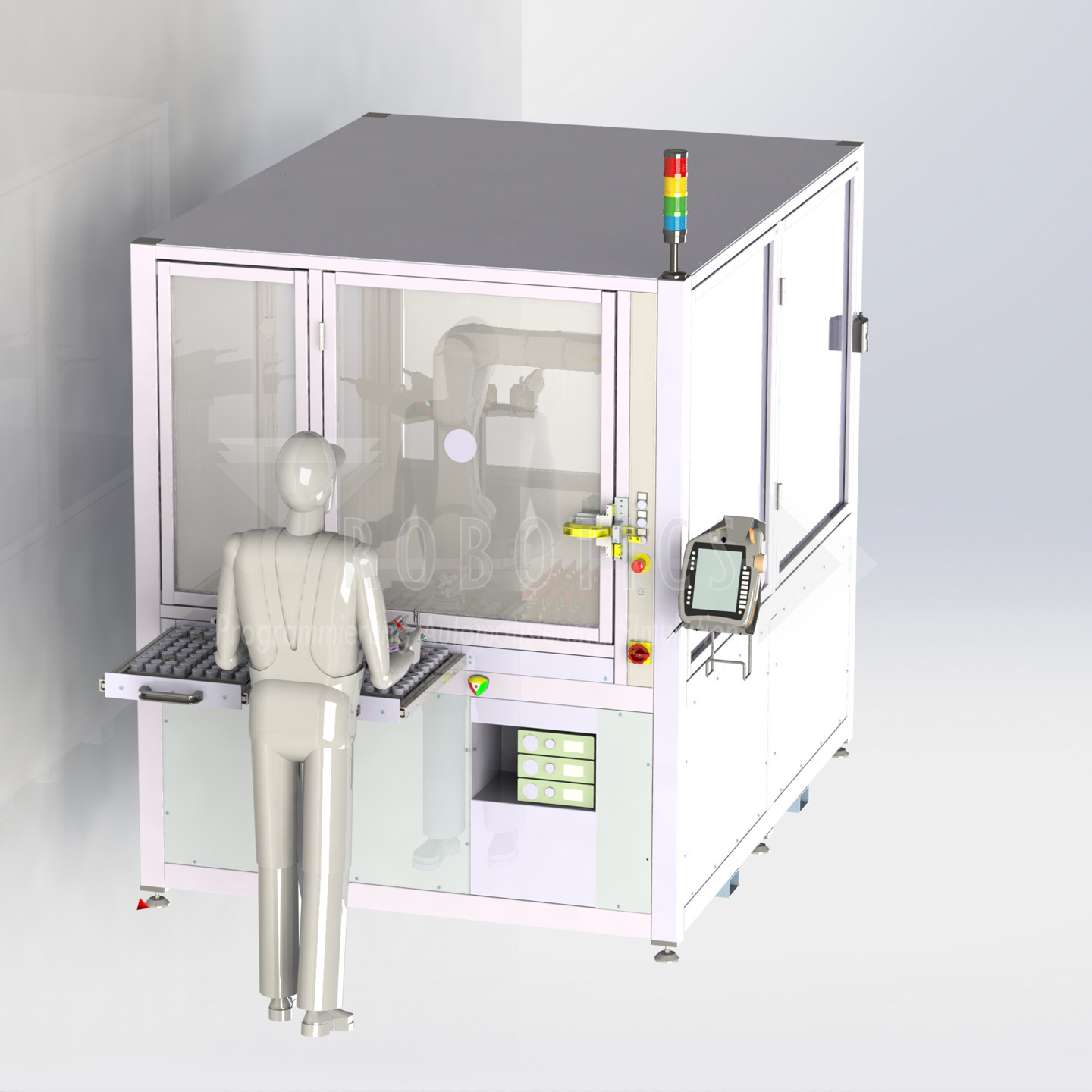

The 3D-process simulation for robot application and Ergonomic design are the focus of our company.

By optimizing of production processes, we consider geometric and physical characteristics of element, component and production equipment.

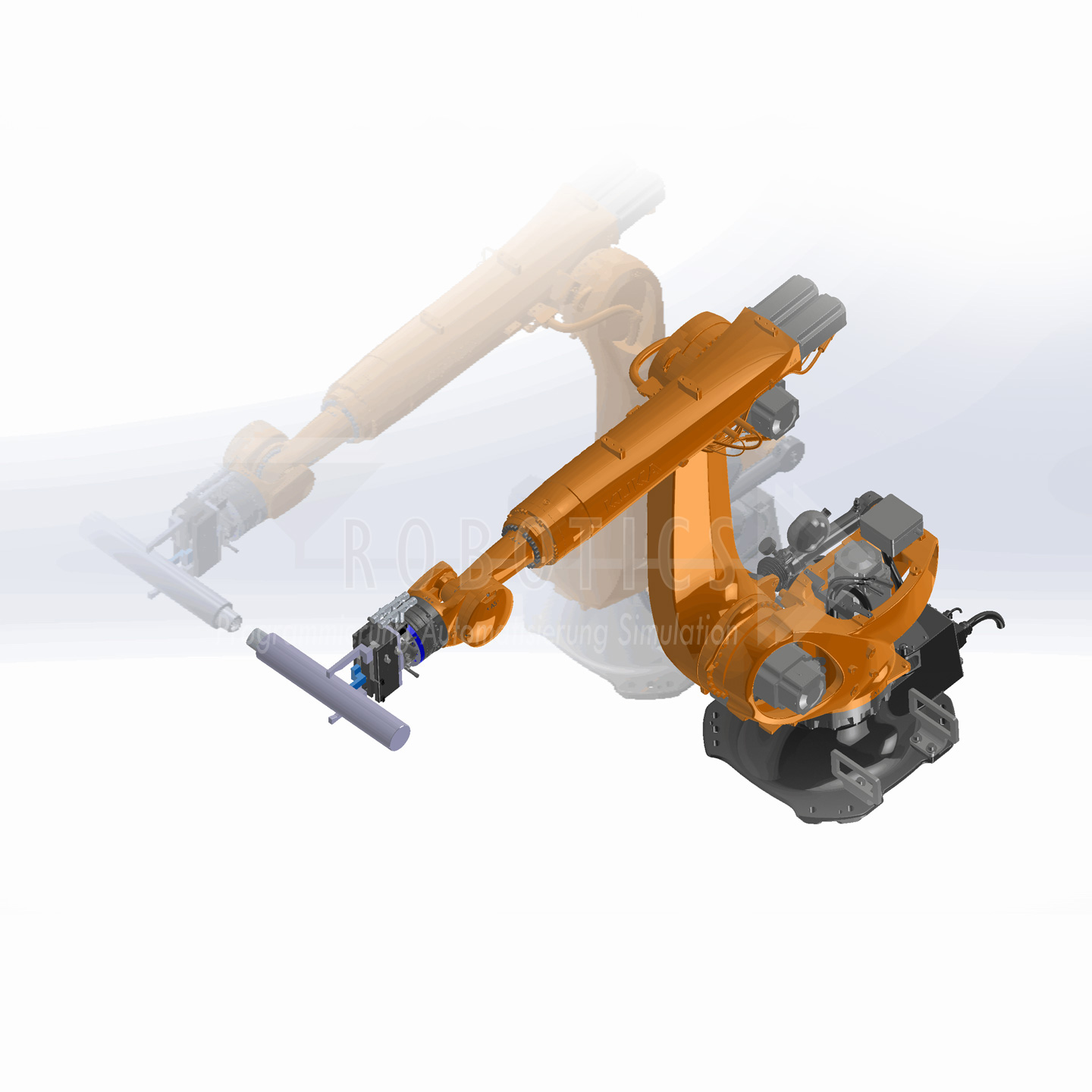

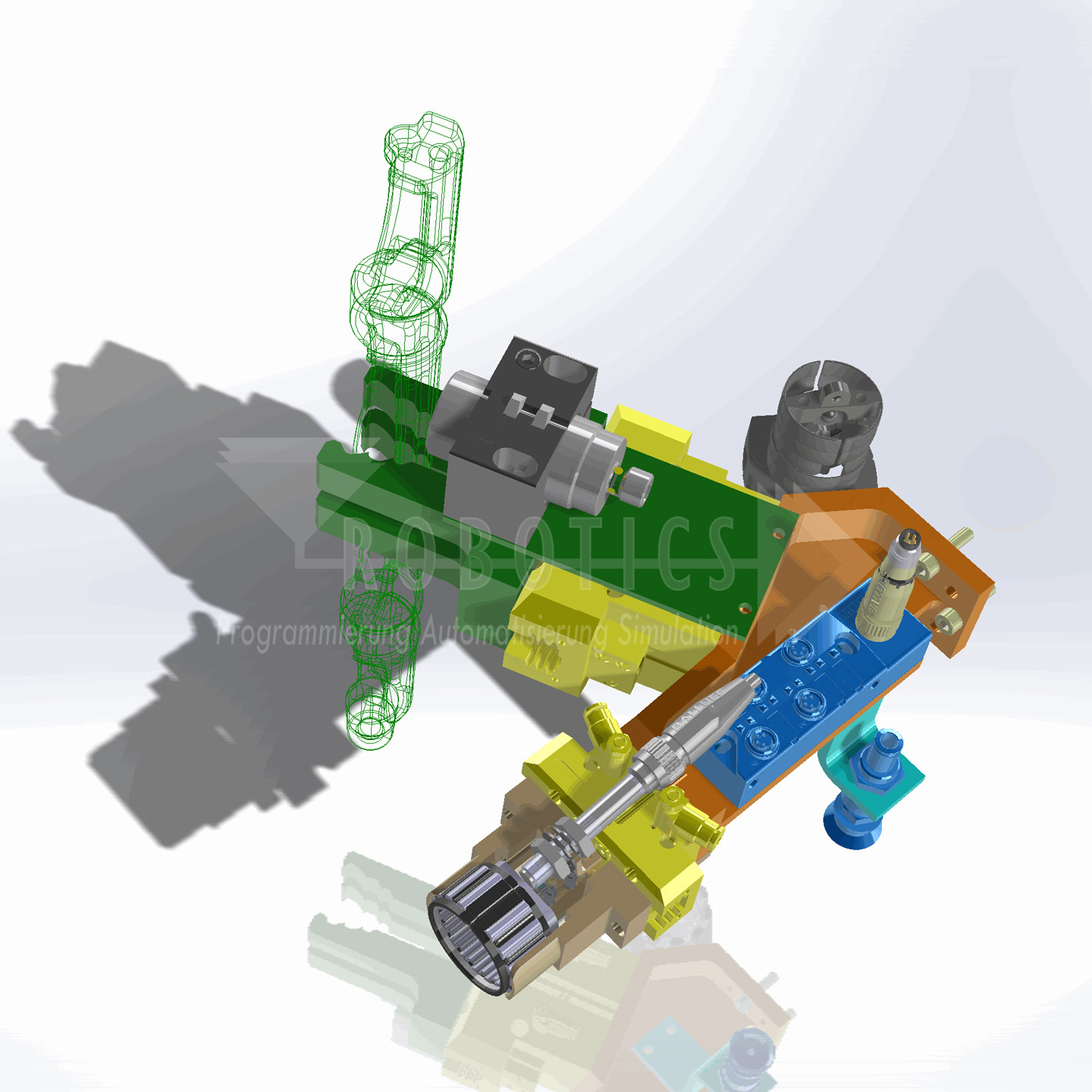

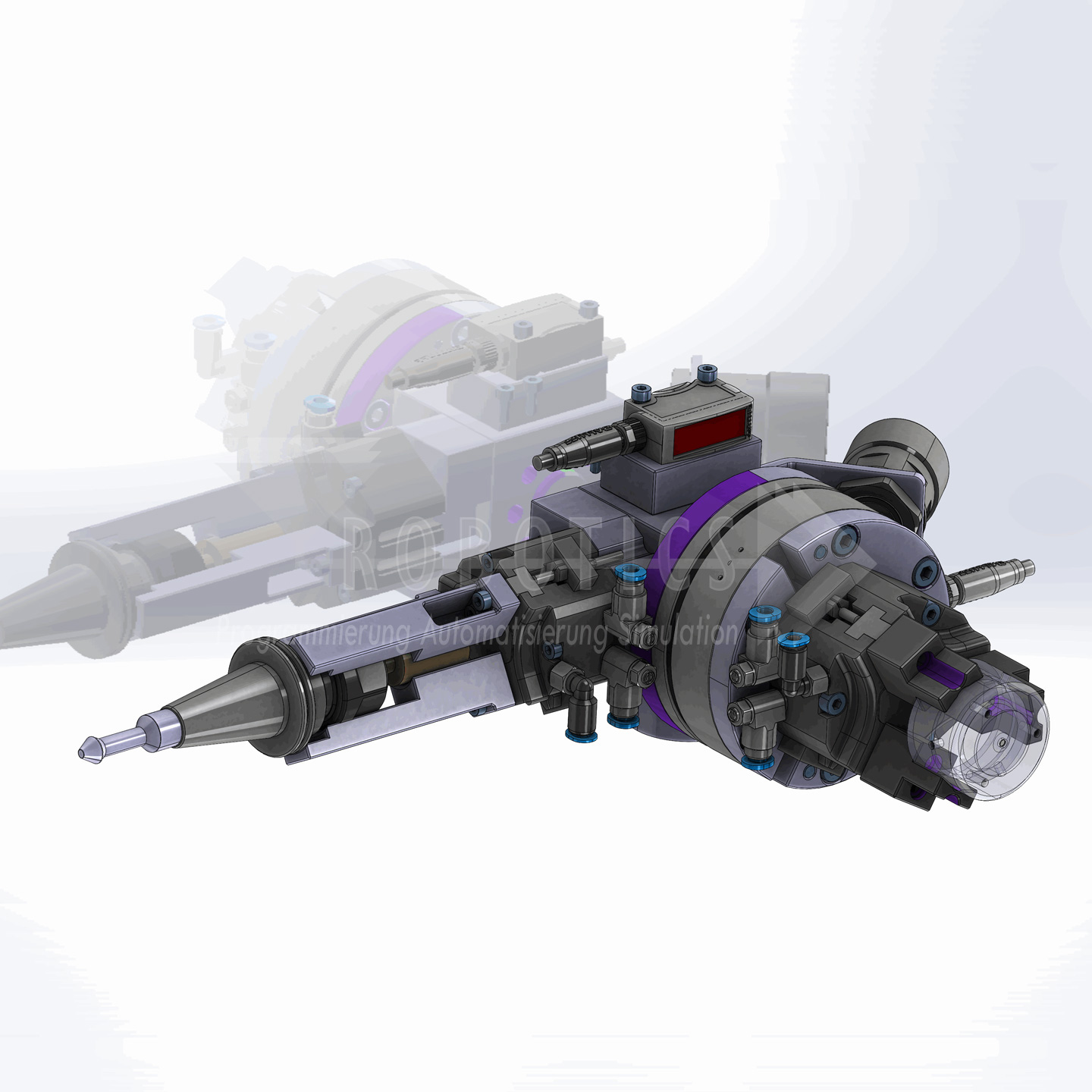

In the application area the complex robot simulation process can be simulated. The design and arrangement of tools, equipment and components, as well as the integration of industrial robots in the environment of the manufacturing cell, can be optimized interactively in the 3D model.

With the assistance of simulation softwares such as ROBCAD, Process Simulate and Delmia, Robot programs are generated, tested and transferred to the production control.

OFFLINE-PROGRAMMING – A PART OF PROCESS PLANNING

Offline-Programming allows simultaneous planning of a product and the production process.

Seamless integration and use of international standard interfaces between CAD and CAPE afford realistic and functional construction of complete sections and production systems.

Before investing in manufacturing facilities, an analysis and optimization on the basis of virtual 3D cells is possible.

Typical applications are: 3D-Graphic simulations, modeling of kinematics, motion planning, collision recognition, dynamic analysis, determining cycle time, On/Off-Communication or process-based procedures for large numbers of processes such welding, riveting, gluing, cutting, assembling, drilling, measuring , folding etc.

We have specialized us on the field in the worlds most trusted CAPE Software ROBCAD.

Thereby, we manage a 3D-visualization of Robots, production facilities and work activities.

With simulation of production cell test, we verify and optimize the allocation of space and process paths of robots and manual tasks.